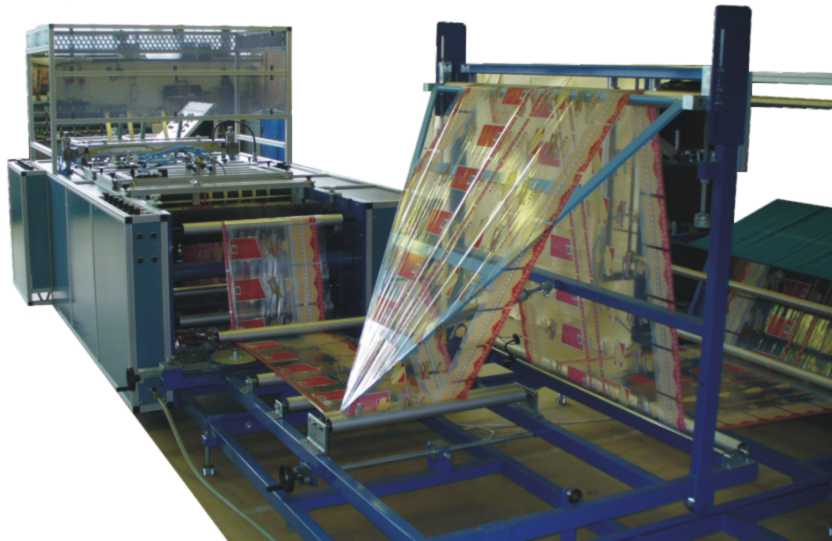

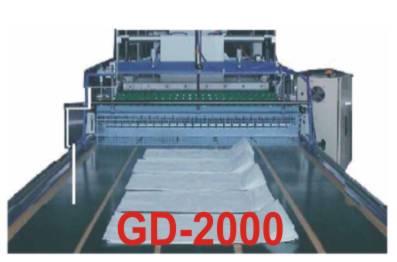

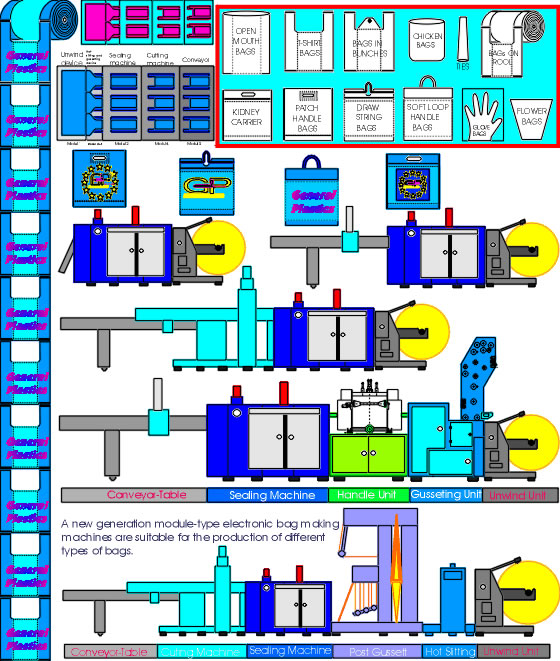

Bag Making Machines

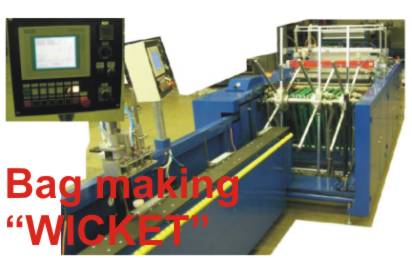

New generation module-type electronic bag making machines. 1;2;3;4-lines

General Plastics GmbH builds a new generation of electronic BAG MAKING MACHINES that, equipped with a large range of ancillaries, are suitable for the production of different types of bags. A computer controller makes the programming easier, stores the standard production and manages each work clearly.

MAIN CHARACTERISTICS:

- High speed line for producing every kind of bags, collected on pins or conveyor.

- The type of production may be instantly changed by preselection on the control monitor, without changing the equipment.

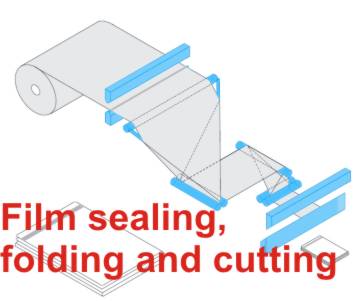

- Film advancement and controlled by electronic system.

- Stabilised welding bar with Ni / Cr strip, closed-circuit liquid cooling system.

- Oscillating stacking system of bags to avoid the sticking of the weldings.

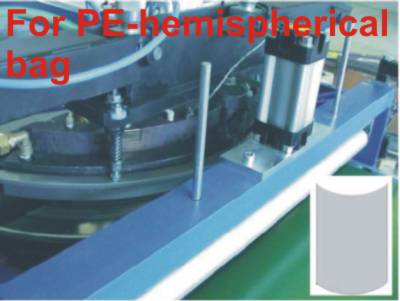

- Machines with a hollow punch for bags with automatic welding, cutting, laying on rotating plates or rotating pick-up and laying on a rotary conveyor.

- Monitor for the electronic control of working cycles, signals and instructions to Eliminate the Causes of stopping.

- Group for: reel-holder - cut and seal unit - gusseting unit - stacking table - available in a variety of models According to customer demands.

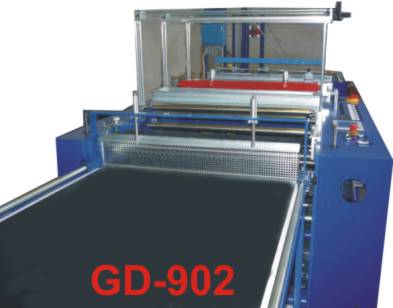

| MODEL | GD-402 | GD-502 | GD-702 | GD-902 | GD-1302 | GD-1502 | |

| NUMBER OF TRUCKS | pcs | 1 | 1 | 1;2 | 1;2;3 | 1;2;3;4 | 1;2;3;4 |

| WELDING WIDTH MAX. | mm | 400 | 500 | 700 | 900 | 1300 | 1500 |

| BAG LENGTH MAX. | mm | 150-650+x | 150-650+x | 150-700+x | 150-800+x | 150-1000+x | 200-1000+x |

| REEL DIAMETER MAX. | mm | 600 | 600 | 600 | 600 | 800 | 900 |

| FILM THICKNESS | mm | 0,008-0,15 | 0,008-0,15 | 0,008-0,15 | 0,01-0,15 | 0,01-0,2 | 0,01-02 |

| MECHANICAL SPEED (cycle/min./truck) |

pcs | 150-200 (300) |

150-200

(300)

|

150-200 (300) | 150-200 (300) | 150-200 (250) | 150-200 (250) |

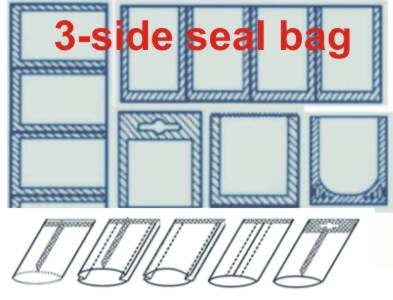

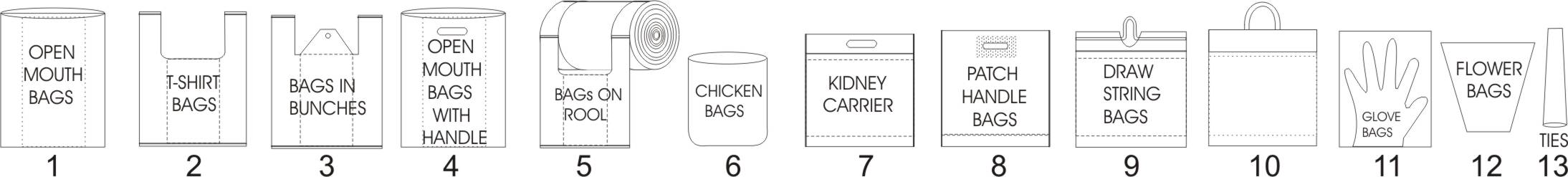

The main types of bags. For inquiry or order please give the the type of bag or send a drawing, photograph or bag sample.

GALLERY

*MACHINE WITH SERVO MOTOR AND COMPUTER CONTROLLER