Film Blowing Machines

Complete blown film systems for single or multi-layer films up to seven layers of HDPE, MDPE, LDPE, LLDPE, MPE, EVA, PP, PA, EVOH, PET, PS, Ionomers, Blends and Reclaim.

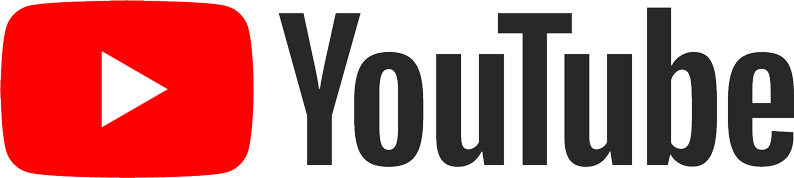

SINGLE LAYER FILM BLOWING MACHINES

The BLOW FILM EXTRUSION LINE is the most important for General Plastics. Our experience in this field is the result of many lines sold all over the world. We can offer to our clients a complete range of films extrusion lines with the most advanced technology. The extruders are outstanding for their performance characteristics: high productivity, excellent material plastication, efficient temperature control of the barrel, speed control by inverter, low energy consumption, dependability and application flexibility. Centre-fed BLOWING HEADS are with spiral-type mandrels. Available in stationary or rotating version, single-layer or multi-layer.

Body and dies are made of special steels. COOLING UNITS for external bubble cooling, consisting of cooling rings with their blowers, air hoses and boxes. The rings are made of aluminium.

TAKE-OFF UNITS are available in several dimensions and versions. WINDERS available in several dimensions and version, single or dual- station, economical design or semi- automatic. Our CONTROL is extremely practical and easy to use. The real saving in raw materials, the constant quality on the film being made.

MULTI-LAYER FILM BLOWING LINES (2-7 layers)

Important part of G.P. Extrusion product range, multi-layer blown film lines provide solutions for industrial and food packaging, as well as for technical and agricultural applications. We can offer you complete range of machinery and lines for LDPE, HDPE, LLDPE, Metallocene, PA, EVA, PP, EVOH, and special resins.

We can deliver a taylor-made line designed in conformity with specific production targets and quality standard of the client. A successful company is carried by excellent ideas - ideas with the dynamics to give the company meaning, growth and future. With our extrusion lines you can produce stretch film, thermoshrinkable film, film for production of various types of bags, diapers,food packaging, coextruded film for the most diversified packaging applications and for agricultural applications.

| MODEL | GF- 30H/400 30L/400 30HL/400 | GF- 35H/500 35L/500 35HL/500 | GF- 40H/700 40L/700 40HL/700 | GF- 45H/900 45L/900 45HL/900 | GF- 55H/1200 55L/1200 55HL/1200 | GF- 65H/1700 65L/1700 65HL/1700 | GF- 80H/2200 80L/2200 80HL/2200 | GF-100L/2800 120L/3500 |

| FILM THICKNESS (mm) | H:0,008-0,1 L:0,010-0,15 | H:0,008-0,1 L:0,010-0,2 | H:0,008-0,1 L:0,010-0,2 | H:0,008-0,1 L:0,010-0,2 | H:0,010-0,1 L:0,010-0,2 | H:0,010-0,1 L:0,010-0,2 | H:0,010-0,1 L:0,020-0,2 | L:0,035-0,2 |

| SCREW DIAMETER (mm) | 30 | 35 | 40 | 45 | 55 | 65 | 80 | 100 / 120 |

| FILM WIDTH RANGE (mm) |

H: 100-350

L: 100-350 |

H: 150-450

L: 150-450 |

H: 150-600

L: 150-600 |

H: 250-800

L: 250-800 |

H: 300-1100

L: 400-1100 |

H: 500-1500

L: 500-1500 |

H: 700-2000

L: 700-2000 |

L:1000-2600 1000-3300 |

| ROLLER WIDTH (mm) | 400 | 500 | 700 | 900 | 1200 | 1700 | 2200 | 2800 / 3500 |

GALLERY

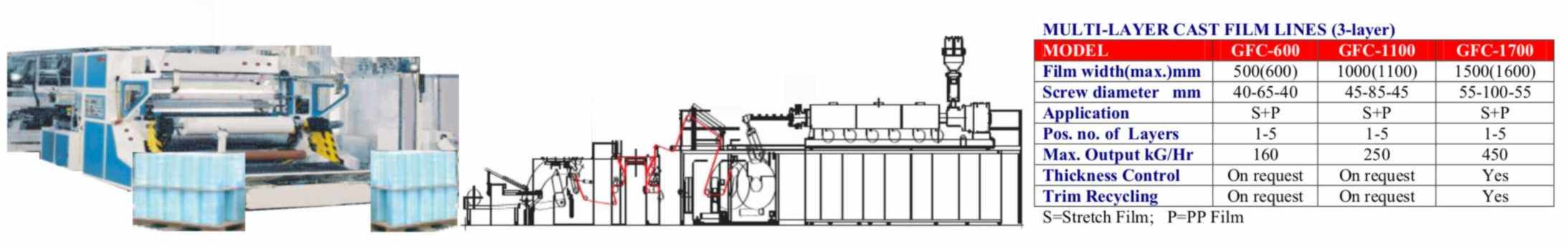

MULTI-LAYER CAST FILM LINES

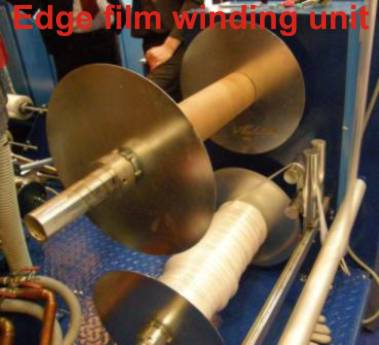

WINDING UNITS

GALLERY

OTHER MACHINES

GALLERY

PERIPHERIAL EQUIPMENT

GALLERY

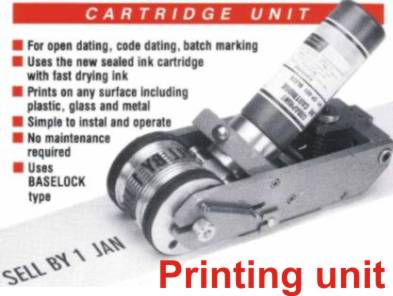

OPTIONAL EQUIPMENT: EMBOSSING ROLLER, FILM SURFACE TREATER , AUTO FILM WIDTH CONTROLLER, ROTATING DIE MECHANISM, BACK TO BACK WINDING UNIT, AIR COMPRESOR , AUTO LOADER, MICROPERFORATING UNIT